|

SOLVENT PERFORMANCE TEST iBiotec OPERATING MODE |

|

WITH CLOTH TEST |

A- SUBJECT This procedure deals with the method for checking the effectiveness of a degreasing operation using the white cloth test. |

|

CONDITIONS BEFORE CLEANING |

NONE |

HEATING OF THE POLLUTED LID TO 100°C FOR 6H |

UV EXPOSURE OF THE COVER POLLUTEDFOR 3H |

|

CLEANING METHOD |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Note the dissolution times for each method.

After cleaning, allow the surfaces to air dry for 1 night or put them in a drying oven for 10 to 20 minutes.

|

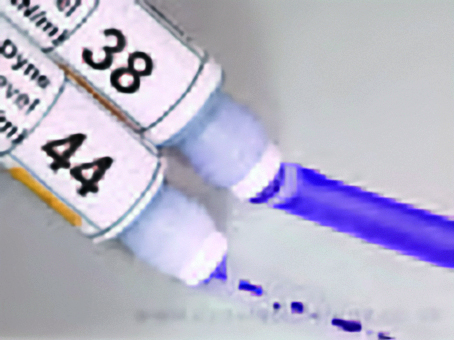

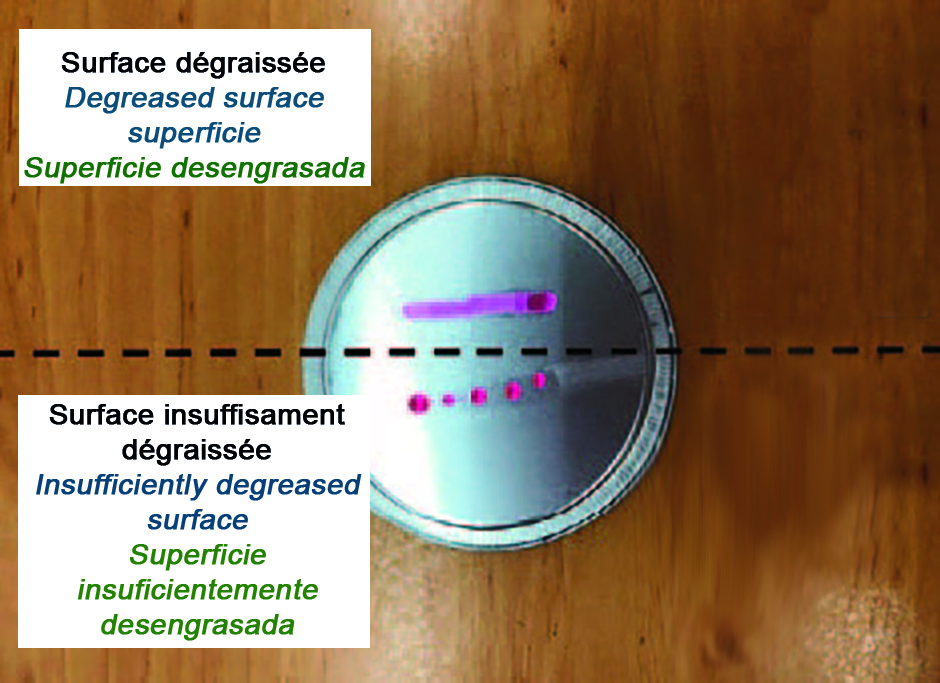

C- RESULTS Wipe the surface of the lid with the white cloth. If there are any coloured marks on the cloth, this means that grease is present. Degreasing will therefore not be effective. If the cloth stays white, this means that the surface is clean. |

|

SOLVENT PERFORMANCE TEST iBiotec OPERATING MODE |

|

INK OR PEN SURFACE TENSION MEASUREMENT TEST |

A- SUBJECT This procedure deals with the method for checking the effectiveness of |

|

CONDITIONS BEFORE CLEANING |

NONE |

HEATING OF THE POLLUTED LID TO 100°C FOR 6H |

UV EXPOSURE OF THE COVER POLLUTEDFOR 3H |

|

CLEANING METHOD |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Note the dissolution times for each method.

After cleaning, allow the surfaces to air dry for 1 night or put them in a drying oven for 10 to 20 minutes.

| * Dissolution in the solvent whose effectiveness is to be tested. Disolución en el disolvente cuya eficacia se desea comprobar. ** Place the lid in a 2000 ml beaker with the solvent whose effectiveness is to be tested, filled to 1000 ml. |

|

SOLVENT PERFORMANCE TEST iBiotec OPERATING MODE |

C- DETERMINING SURFACE TENSION

C.1 Method for determining surface tension

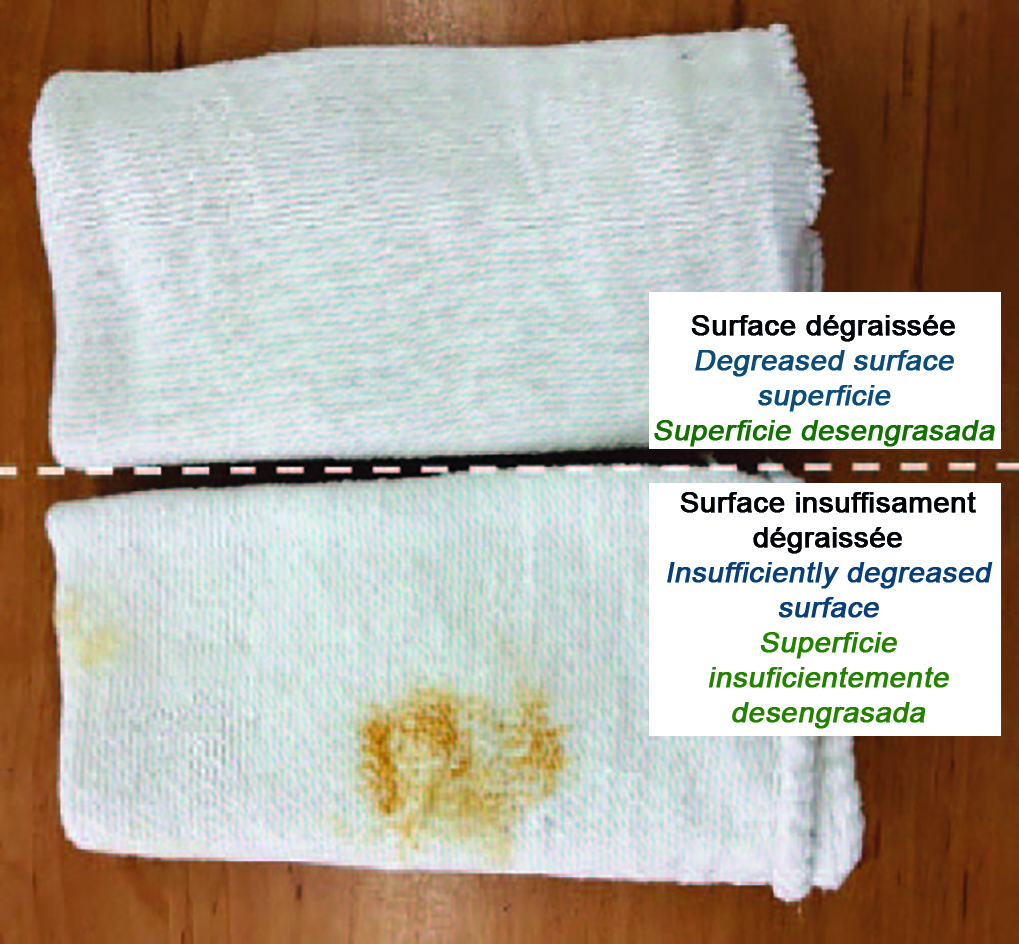

Use the pen or ink to make a line (5 to 20 cm long) whose surface energy value is the lowest (30 mN/m).

Repeat this step by increasing the value of the pen or ink. If the deposited ink contracts and forms small drops (see picture below), this means that the surface energy is less than the product’s. On the other hand, if the film that forms is clear and uniform (see photo below), the substrate’s surface tension is equal to or less than the ink’s.

|

|

Example: In the photo on the top, the surface tension of the surface is ≥ 38 mN/m and < 44 mN/m

|

|

D- RESULTS |

|

|

SOLVENT PERFORMANCE TEST iBiotec OPERATING MODE |

|

TEST WITH USE OF A UV LAMP with a 365 to 400 nm wavelength |

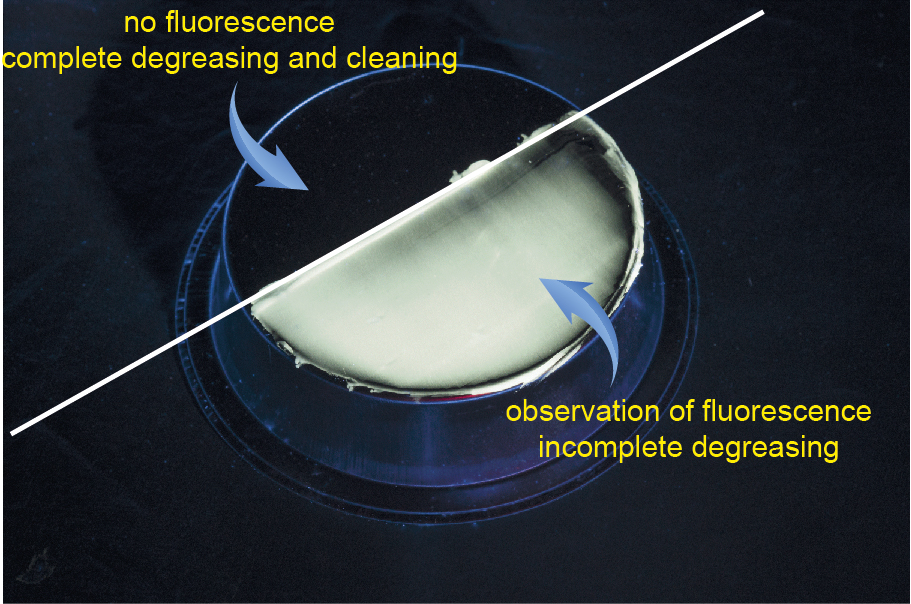

A- SUBJECT This procedure deals with the method for checking the effectiveness of a degreasing operation using a UV.A 365 to 400 nm lamp. |

|

CONDITIONS BEFORE CLEANING |

NONE |

HEATING OF THE POLLUTED LID TO 100°C FOR 6H |

UV EXPOSURE OF THE COVER POLLUTEDFOR 3H |

|

CLEANING METHOD |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

Dissolution* by dipping

Dissolution** in a US tank (to simulate mechanical agitation) |

After cleaning, allow the surfaces to air dry overnight or put them in a drying oven for 10 to 20 minutes.

Place the lids in a black cabinet (or in a completely black room) and illuminate them with a UV.A 365 to 400 nm lamp (with a 365 to 400 nm wavelength).

C- RESULTS

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.